raw materials for stone crusher industry

crushing cement raw materials Crushing and grinding of raw material in a cement industry Stone Crushing Raw Materials Types. Copper Ore Crusher; Cement Raw Materials Crushing .

WhatsApp)

WhatsApp)

crushing cement raw materials Crushing and grinding of raw material in a cement industry Stone Crushing Raw Materials Types. Copper Ore Crusher; Cement Raw Materials Crushing .

Polishing rocks is a satisfying hobby, but the use of a rock tumbler to achieve the polished result is surprisingly unnecessary. With a few simple materials and some elbow grease, even the most novice rock hound can create beautiful polished stones and gems from .

Grinding Process. The grinding wheel consists of several abrasive particles which act as minute cutting edges, and these particles are bonded with the help of bonding material. The advantage of using such a process over conventional metal removal processes are as follows. The rate of removal of material is much higher than, say, a traditional file

DEIPA, raw materials for grinding facilitator, which is quality enhancer used in cement, could improve the dispersion, reduce the the energy consumption of electric, save time and reduce the wear and tear of the machines.. packing: 220kg/drum; 1050kg/IBC; 21MT in a flexytank; ISO tanks, could according to the require of customers. Storage: Keep in wellventilated place and free from exposure ...

Abrasive, sharp, hard material used to wear away the surface of softer, less resistant within the term are both natural and synthetic substances, ranging from the relatively soft particles used in cleansers and jeweler''s polish to the hardest known material.

Order Dremel Stone, Grinding, 3/8 In, 932 at Great prices free shipping on orders over USD50!

When using your grinding disc, you''re basically removing unwanted stone and metal materials at faster rate and in an easy way than if you used a handheld single edged tool, like a chisel. Of course, a grinding wheel works more like a file, a very highspeed file, using multiple edges to cut away at your raw materials.

Experiment 3: grinding various types of material with handstone and grinding stone. 37 Purpose: test the impact of various worked materials on use wear. 38 Experimental material and protocol: experiment 1 showed a low variability of use wear depending on the type of basalt; therefore the raw material parameter was not systematically taken into ...

Polishing rocks is a satisfying hobby, but the use of a rock tumbler to achieve the polished result is surprisingly unnecessary. With a few simple materials and some elbow grease, even the most novice rock hound can create beautiful polished stones and gems from a jagged collection.

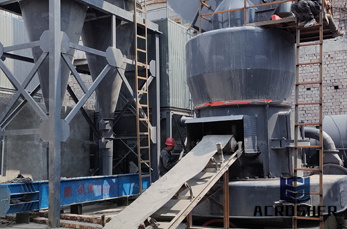

Raw Mill Cement Liners. Raw mill is mainly used for grinding cement raw materials. It can also be used for grinding various ores and other materials in electric power, metallurgy, chemical industry and other industry. Get Price And Support Online; Raw Mill Cement Liners caringhearts. The Selection and Design of Mill Liners. Get Price []

Cup grinding wheels, sometimes called cup wheels, have abrasive material on the side of the wheel for cutting, grinding, and finishing metal, wood, glass, plastic, cement, ceramic, and composite materials. They''re designed for use with bench or angle grinders.

industrial stone grinding,process,machinery raw . industrial stone grinding,process,machinery rawmaterial and other n/info ... stone grinding... Raw material: ... Get Price; Mill (grinding) Wikipedia. Other names: Grinding mill: ... usually stone or metal, which grind material to the ... one example being the Sepro tyre drive Grinding Mill.

Given that the use of jappenyin requires raw material preparation on the surface, and given that the standard Kriol translation of jappenyin is ''flat rock'', one hypothesis would be that jappenyin is a subclass ''flat grinding stone'' of a more general superclass garradin noberlberlin ''flat stone''.

Dec 03, 2019· Phase 1: Crushing the raw materials. Marble blocks are crushed by the crusher to the size of 15mm50mm and into grinding mill. Phase 2: Grinding. The crushed coarse marble are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding. Phase 3: Classification

The main raw materials used in the cement manufacturing process are limestone, sand, shale, clay and iron ore. process. It is mined, usually from a quarry loed near or adjacent to the cement plant. Mining of pieces. Horizontal rotating drum grinding mills tumble steel .

In cement: Grinding. The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. The material may pass straight through the mill (opencircuit grinding), or coarser material may be separated from the. Read More; cutlery. In cutlery: Cutlery manufacture

dry raw material grinding ball mill machine ball mill; dry raw material grinding ball mill machine ball mill. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump.

A grinding wheel is a wheel composed of an abrasive compound and used for various grinding (abrasive cutting) and abrasive machining operations. Such wheels are used in grinding machines.. The wheels are generally made from a composite material consisting of coarseparticle aggregate pressed and bonded together by a cementing matrix (called the bond in grinding wheel terminology) to form a ...

2. A grinding tool for nonmetallic materials such as stone materials. 3. The utility model has high grinding performance and can be used for nail art. 4. There are cylindrical grinding heads and bulletshaped grinding heads. 5. It adopts highquality Luogangyu raw materials with high hardness, good wear resistance and uniform particles. Using: 1.

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

raw materials to gold mining Crusher Machine For Sale. Crusher Machine For Sale. The XSM is professional ore crushing machinery company,the company''s crushers machine for sale main stone crusher,grinding mill,sand making.

Raw Gold Ore Processing Plant Cost Of Grinding In Gold Production. What is the Cost of Mining Gold Visual Capitalist. 7 9 2016· The processing begins with Bauxite Calcination Plant Cost Bauxite Ore Dressing Equipment In order to produce further valueadded material from plant grade bauxite the bauxite ore processing .

Granulation or Coarse grinding size reduction is offered for raw materials in large forms such as sheets, lumps, purgings, cylinders, rods, tubes, blocks, bales, slabs etc.—most any shape, as well as for scrap materials to be recycled such as parts, sheets, pipe, profiles, bottles, etc. Large raw materials are generally granulated to a particle size of 3/8" but any size larger or smaller can ...

Raw Materials of Salt Feldspar crusher XSM Machinery (Raw Materials of Salt) in mineral processing aspects widely used, many customers get more benefits, XSM product also mainly for minerals, rock crusher, mineral grinding, sand stone and mineral processing.

WhatsApp)

WhatsApp)