Grinding concrete trip hazard repair YouTube

Aug 20, 2018· DIY Sidewalk raised crack, trip hazard repair by grinding down, using angle grinder with masonry blade and an Integra diamond cup wheel

WhatsApp)

WhatsApp)

Aug 20, 2018· DIY Sidewalk raised crack, trip hazard repair by grinding down, using angle grinder with masonry blade and an Integra diamond cup wheel

Concrete Grinding is a modern technique to eliminate trip and fall hazards. The process uses a Scarifier Concrete Grinder and Dry Surface Grinder to sand down the raised side of two joining sections of concrete.

Apr 02, 2020· After around 12 hours of grinding, only around 1/5th of the wheel is gone, so this thing lasts a long long time. It''s great for levelling concrete floors, or grinding down high spots, such as between different areas. When grinding with this cup, and without a dust shroud, it might be useful for you to splash water on the concrete.

2. or hire someone to grind down the slab region that is higher; big expensive messy job. 3. or tear out all of the wood floor and bring the other slab higher; very expensive reflooring of almost the whole house. 4. or create a floor transition between tile and wood that has a stepdown to the lower wood floor.

1. Protect any livedin areas before you grind concrete, as concrete dust is harmful to the lungs, eyes, furniture and other items. Cover all doorways with plastic sheeting.

With grinding diameters of 5 inches or less, these tools can''t replace walkbehind surface preparation machines for profiling large areas of concrete. But they work easily in tight areas where the larger units can''t maneuver, such as in corners and close to walls.

Oct 14, 2019· As needed, use a concrete grinder (you may want to rent one) to remove any coating and to slightly roughen the concrete surface so the adhesive will stick. If you are installing a locking or floating floor not attached to the subfloor, just make sure that the subfloor is .

The kind of tool you use in grinding concrete floor high spots determines the quality of your concrete repair. A walkbehind heavyduty grinder with diamond blades on the bottom gives great results. But be careful. The blades in this machine cut so rapidly that a small .

Sep 18, 2012· Grinding concrete down to level is about the least efficient method of leveling concrete, the best way is to place forms at the correct elevation, then screed with a screed board, which can be a 2x4 (make sure it is dead straight), or a steel angle.

Jan 24, 2019· Leveling Uneven Concrete with Grinder. Hello, Friends!! Thank You for visiting my channel. Today I will share with you an Idea on how to level uneven concret...

Concrete grinding or sidewalk cement grinding is one method to remove sidewalk trip hazards typically up to 1 1/2″ in height where sidewalks have been lifted by tree roots, shifting soil, etc. Concrete grinding will remove the top finished layer of cement and leave an exposed aggregate finish where the concrete trip area has been removed, but ...

Concrete is often ground down to obtain a glasslike smooth finish. There are various tools used for grinding concrete. The floor grinder is used to grind and smooth large concrete floors; the rightangle grinder is used to grind and smooth corners and concrete countertops; the belt sander is used to grind countertops and small floors and the orbital sander is used to place a fine, smooth ...

Ensure that the concrete is dry when you begin to grind with the use of a cup wheel. If the area is wet, use a ground fault circuit interrupter so you don''t get electrocuted. Once done grinding, ensure that the garage floor is totally free of dust. 0. SHARES. Share Tweet. 2 Comments.

May 22, 2020· Selecting the correct angle grinder for concrete grinding purposes is very important. You can choose either a 4inch angle grinder or one that is 4 ½ inches. These are considered the best for most concrete grinding tasks. It may also be a good idea that you choose a tool with a motor that is able to draw anywhere between 5 – 9 amps.

Tools Needed to Grind Concrete Floors. Having the right concrete floor grinding tools is essential for achieving a perfectly polished floor. Kits . Before commencing the concrete floor grinding process, it is essential to have the floor checked for any cracks or damages. A floor repair kit will come in handy in case of any repair needs. 2.

Aug 21, 2017· Concrete grinding is actually a lot easier than I thought it was going to be. Obviously, this depends so much on what you are trying to do and the circumstances, but the basic operation of the machines was easier than expected. I definitely had some issues that if avoided, would have help the job go faster and the results would have been better

For smooth finishes and removing minor imperfections, use 80 to 120grit sandpaper. For the smoothest finish use superfine sandpaper, 200 to 400grit or higher. If you use a wetdry sandpaper, you can wet the area before you work to keep dust down. Do not let the slurry dry on the concrete because it .

Aug 24, 2020· Grind down all the spots you marked with an "X" with the chalk, then vacuum up the dust with a shopvac. You can rent a concrete grinder for the job at most home center stores. Remember that you will have to get the grinder up and down the stairs if you are working in a basement.

Jun 16, 2016· That would make the most down exposed aggregate just seems like opening a can of worms. Grind too little and you now expose more sharp edges, grind too much and you have a slick surface (much like poured concrete flooring) that is a huge headache in wet areas.

Dec 01, 1990· Lowell Brakey, a Kansas concrete contractor, has developed a slick way of doing this. His crew puts water on the floor to find the high spots. Then they grind the spots down using a walkbehind heavyduty grinder that looks like a floor buffer but with diamond blades on the bottom.

Oct 05, 2017· Join Vicki Steph from Mother Daughter Projects as they show how to fix raised concrete with an angle grinder. For more details and tools list visit: http:/...

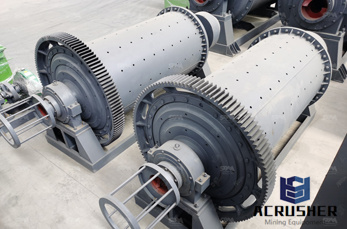

The concrete grinding machines mostly use some sort of abrasive such as diamond or silicon tools to grind. Diamond tools used for grinding usually are usually diamond grinding cup wheels. The machines come in a variety of sizes with quality of finishes determined by the grits in a machine.

Dec 12, 2018· A concrete grinder uses diamonds, or sometimes tungsten, to grind off layers of concrete. Most people use a concrete grinder to remove very small amounts of concrete, or to remove glues and imperfections from concrete. You can expect on most passes you are going to take off around 1/16″ of concrete with normal grinding wheels and work.

Oct 22, 2019· A tangent video on a recent house project, resurfacing concrete in preparation for painting. Help me continue making science videos https://

WhatsApp)

WhatsApp)