Robotics, driverless tech are taking over mining jobs ...

The mining industry employed 634,600 people in 2014, according to data from the National Mining Association. It created another million indirect jobs. Coal mining, because of coal''s ...

WhatsApp)

WhatsApp)

The mining industry employed 634,600 people in 2014, according to data from the National Mining Association. It created another million indirect jobs. Coal mining, because of coal''s ...

Coal blending is the process of mixing coals after coal has been mined to achieve quality attributes that are desirable for the coal''s intended application ( steam generation, coking). The quality attributes that are most important in blending will differ from one mine site to another and also depend on how the coal seams vary in quality and their final intended use.

SGS global teams of chemists and experts use a range of coal analytical calculations and indexes to arrive at the calorific values, total hydrogen, Coke Reactivity Index (CRI) and Coke Strength after Reaction (CSR) of your coal sample.

Aug 17, 2019· What fuel is used to power coal mining machines? Both diesel and electricity are used for coal mining. The largest machines tend to be electric. 36. ELECTRIC COAL MINING MACHINERY This works, because they don''t move very fast, so the AC cord sit t...

Learn about the sorting, blending, and analysis technologies used in coal mining to meet customer requirements and keep workers safe from coal dust. Operation and Maintenance of Coal Handling System in Thermal . equipment includes crushing and sieving, coal blending and coal supply, Removal Iron, weigh, sample, dust removal equipment.

Buying Coal. Leave the locating of highquality coal to us. We will assist you with determining the coal quality and market type that you need. Market types include blue gem coal, cooking coal, industrial coal, metallurgical coal, silicon coal, steam coal, and coal for export.

The Salem 1500B coal auger is a smaller, easily transportable coal auger. The Salem 1500B can handle augers 16″30″ in diameter. The machine is designed to fit well with haulback systems and can work highwall lengths of just a few hundred feet. Only the skids and pan conveyor need to .

Nov 28, 2018· Coal mining has been performed since the arrival of the Industrial Revolution in the mid18th century. Coal is used as a fuel primarily for steamgenerated electrical power plants, as well as being a component of certain industrial applications, such as steel manufacturing.

A. Abutment In coal mining, (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides, which act as abutments of the arch of strata spanning the roadway; and (2) the weight of the rocks over a longwall face is transferred to the front abutment, that is, the solid coal ead of the face and the back abutment, that is, the settled packs behind the face.

Blending of two or more gases. Diffuser fan — A fan mounted on a continuous miner to assist and direct air delivery from the machine to the face. ... Undercut — To cut below or undermine the coal face by chipping away the coal by pick or mining machine. In some localities the terms "undermine" or "underhole" are used.

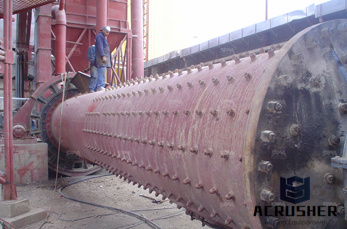

Blending To Crusher Mining Trishnacoin. Blending to crusher mining copper concentrate blending equipment in australia copper concentrate blending equipment in australia 42 Views The is the Get Price mining machine Mining CrusherMining Equipment Mining crushers mainly include jaw crusher cone crusher impact crusher Cement is manufactured by ...

Coal Sampling Systems for Use in Coal Mining Coal Power Generation. ... When combined with coal blending software these unique instruments offer the most effective way to minimize variations in coal quality, ensure contract compliance, and improve efficiency.

Mining Machine for Coal Crushing. Mining Machine for Coal Crushing (capacity: 4000 t/h). from Zhenyuan Machinery, since 1964! The values in this table represent a typical sizer and are dependent on the tonnage rate and tooth configuration required.

What is Mixing, Blending? "Mixing is the process of thoroughly combining different materials to produce a homogenous product." The mixture is generally a combination of dissimilar materials, coal ash and cement are blended in a specified ratio to produce Pozzocrete cement.

Mar 02, 2011· WV Coal Mine, 14/15 Continuous miner Removing a "stump" of coal. His Veins Run Cold When He Realizes Who''s Been Haunting The Homestead All Along .

Improving fundamental stockpile management procedures P. Keleher D. Cameron ... Coal Quality management and the control of the flow of coal through complex mining preparation and transport phases ... 3. prior to the washplant for raw coal blending into the plant to maximise yield.

blending of iron ores shibangchina. Coal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US12 billion which could be used for the generation of electric power.

It is now more than eight years since the 2009 Law on Mineral and Coal Mining No. 4 of 2009 (the "Mining Law") was promulgated. While various implementing regulations, including a number of amendments, have been issued by the Government in pursuing the goals of the Mining Law, there remain many challenges for investors, particularly in the

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United Kingdom and South Africa, a coal mine and its structures are a colliery, a coal mine – a pit, and the ...

Coal mining by front end loader or excavator into trucks Coal mining rate relatively uniform but subject to surges due to availability of exposed coal Mining exposed coal gives supply from a single source for an extended period. Blending from multiple seams/areas is possible Dilution is from weak floor cleanup due to waste not

blending the coal within the mine (combination of mining units, shifting heads and coal lines), on the stockyard during the stacking or reclaiming process, or in the inplant storage and feeding system. Autonomous stacking and reclaiming The coal can be stacked and reclaimed by various methods in order to provide an adequate treatment of the

Coal mining, extraction of coal deposits from the surface of Earth and from underground. Coal is the most abundant fossil fuel on Earth. Its predominant use has always been for producing heat energy. It was the basic energy source that fueled the Industrial Revolution of the 18th and 19th

Mining Machines. 61 89 7. Glass Piece Broken. 153 211 55. Colored Pencils. 95 132 4. Japan Island Nagasaki. 10 2 4. Botallack Mine. 6 5 0. Botallack Mine. 43 35 6. Silhouettes Coal Mine. 134 168 54. Colored Pencils. 31 44 8. Pit Mine Hole Open. 5 0 2. Landscape. 30 38 4. Tunnel Mining Mine. 136 158 8. Mining Excavator. 59 82 3. Japan Island ...

Jan 14, 2019· The yearly average in coal mining decreased to 30 fatalities from, though 60 to 70 miners still die each year in the coal and noncoal mining industry. The most common accidents occurring in the mining industry are the result of poisonous or explosive gases or mishaps relating to the use of explosives for blasting operations.

WhatsApp)

WhatsApp)