cement production line YouTube

Aug 05, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Aug 05, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

In the course of cement processing plant, limestone is the largest amount of raw materials for cement production, the larger the particle size after mining, high hardness, thus crushing the material crushing limestone cement making plant occupies a more important position. In the cement making plant, fine jaw crusher for cement clinker.

Go To Assam Geography Notes Study Materials Go To Geography Notes Sillimanite, Clay, Sand, Iron Ore, Copper, Gypsum other minerals of Assam. Sillimanite . It is also an important mineral wealth of Assam. The Assam Sillimanite is in the form of massive rock .

China Refractory Ore, China Refractory Ore Suppliers and Manufacturers Directory Source a Large Selection of Refractory Ore Products at copper ore,iron ore,manganese ore from China

Synthesis process of forsterite refractory by iron ore tailings ... A large quantity of refractory materials have been produced from high ... Iron ore tailings are used as raw materials to prepare ...

Oct 30, 2017· Blast furnace refractories: The development of blast furnace ceramic cups is becoming more and more common, but the need for high corrosion resistance refractory applications to ensure the extension of its service life. In addition to changes in d...

REDART – brickred earthenware clay, produced by Cedar Heights Clay Company. RUTILE – Titanium ore, used as source of TITANIUM DIOXIDE, contains iron, other trace minerals – gives tan color, promotes crystallization giving mottled multicolor effects in some HT glazes, or in overglaze stain (very refractory, use sparingly).

Cement is generally divided into ordinary Portland cement, Portland cement with mixed materials and special cement. Ordinary Portland Cement: By limestone, clay, iron ore powder in proportion to grind and mix; at this time the mixture is called raw material. Then it is calcined.

Jun 01, 2017· Select the high density, low water absorption of raw materials, a reasonable level of preparation is the key to make low porosity refractory brick. Refractory brick is made with 50% soft clay and 50% hard clay clinker according to certain granularity requirements. After molding and drying, firing under high temperature of 1300 ~ 1400 ℃.

Galaxy Enterprise is leading manufacturers, exporters and suppliers of refractories and Fire bricks in Rajkot (India). We offer refractories products to our global client in Africa, Saudi Arabia, UAE, Kenya, Tanzania, Nigeria and Turkey.

MINERALOGICAL AND PHYSICAL–CHEMICAL CHARACTERIZATION OF A BAUXITE ORE FROM LAGES, SANTA CATARINA, BRAZIL, FOR REFRACTORY PRODUCTION Thiago Fernandes de Aquino1, Humberto Gracher Riella1, and ...

Iron Production Iron is produced in blast furnaces by the reduction of iron bearing materials with a hot gas. The large, refractory lined furnace is charged through its top with iron as ore, pellets, and/or sinter; flux as limestone, dolomite, and sinter; and coke for fuel. Iron .

Jan 18, 2016· The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into the top, and preheated air is blown into the bottom. The raw materials require 6 to 8 hours to descend to the bottom of the furnace where they become the final product of liquid slag and liquid iron.

In the present study, three batch compositions were prepared utilizing iron ore tailing in the range of 4560 wt%, clay 2535 wt% and feldspar 1520 wt%. The compacts were heated in the temperature range of 1100o1150oC. All the samples heated at 1150oC possess very high cold crushing strength (>150 MPa) and high flexural strength (>60 MPa) with less than % water absorption.

The raw materials are brought to the top of the blast furnace via a skip car powered by winches or conveyor belts. There are different ways in which the raw materials are charged into the blast furnace. Some blast furnaces use a "double bell" system where two "bells" are used to control the entry of raw material into the blast furnace.

Apr 01, 2014· Raw Materials for Refractories: The Global Situation for Supply and Demand Global production of raw materials for refractories will likely face increased energy costs, changes in consumption levels and other marketspecific factors in 2014 and beyond.

PDF | The efficiency of briquetting kaolin raw material in a roller press is investigated as a measure for combatting dust formation during clay firing. It is established that use of a roller ...

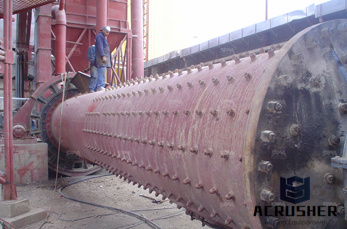

The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill can grind various ores and materials with dry type or wet type. Get ...

heat treatment operations, kilns for cement production, rotary furnaces for iron ore reduction, cast iron and nonferrous metals production, glass melting, heat exchangers etc. The production of various refractory products utilizes raw materials such as kaolinite (Al 2 O 2 O), magnesite (MgCO 3), chromite (FeOCr 2 O 3). The

Raw Materials The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content of these ores ranges from 70% down to 20% or less.

Innovation processes in technologies for the processing of refractory mineral raw materials Article in Geology of Ore Deposits 50(6):491501 · January 2008 with 7 Reads How we measure ''reads''

Refractory manufacturing involves four processes: raw material processing, forming, firing, and final processing. Figure illustrates the refractory manufacturing process. Raw material processing consists of crushing and grinding raw materials, followed if necessary by size classification and raw materials calcining and drying.

What material is used? STUDY. PLAY. Hot surface ingnite. SiN4 or SiC. Alumina. Al2O3 abrasives. Lime. CaO Lowers melting point of glass. Black oxide. Fe3O4 coating for tools. Iron ore. Fe2O3. Salt. NaCl. Soda. Na2O Lowers melting point of glass. Advanced Al2O3. Abrasives. Advanced Zr02. ... Fire clay refractory and mulite refractory ...

metallurgy, De Re Metallica (by Agricola, G., 1556), lists ore, fuel and refractory materials including heat insulators, as the three substances essential for metal refining. All through the Iron Age from ancient times up to now, refractory has been closely engaged in iron and steelmaking, contributing to human civilization.

WhatsApp)

WhatsApp)