Belt Conveyors and Coal Handling Plant Manufacturer | Mech ...

Mech Tech Process Conveying System Belt Conveyors, Coal Handling Plant Chain Conveyor Manufacturer from Chennai, Tamil Nadu, India

WhatsApp)

WhatsApp)

Mech Tech Process Conveying System Belt Conveyors, Coal Handling Plant Chain Conveyor Manufacturer from Chennai, Tamil Nadu, India

Aug 21, 2016· COAL HANDLING SYSTEM Coal Delivery Unloading Transfer Outdoor Storage Covered Storage Inplant Handling Weighing Furnace Firing Preparation / Weighing Shaikh Saif 5. OUTPLANT HANDLING.(COAL DELIVERY) Out plant handling means transfer of Coal from mine or port to storage of coal at plant site. 1. Transportation by Rail: 4000 to 13000 tons/trip.

In a coal based thermal power plant, the initial process in the power generation is "Coal Handling". So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station. The transfer points are used to transfer coal to the ...

Welcome to Schenck Process LLC By combining the technologies of Mac Process, Schenck AccuRate, Stock Equipment Company and Raymond Bartlett Snow to form Schenck Process LLC has resulted in a complete global source of highly accurate industrial solutions for weighing, feeding, screening, conveying, pulverizing, classification, thermal ...

Dec 13, 2019· Power Plant Engineering, Coal Handling, Coal Transfer, Pulverized Coal Handling. Power Plant Engineering, Coal Handling, Coal Transfer, Pulverized Coal Handling.

Our pneumatic conveying systems handle a multitude of dry bulk materials for countless industries—from manufacturing to transportation, energy to utilities, and much more in between. Whether you need to transfer material, bag it, unload it, or convey it over long distances, we have the exact process equipment to meet your specific needs.

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt ...

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transportation of heavy or bulky materials. Conveyor systems allow quick and efficient transportation for a wide variety of materials, which make them very popular in the material handling and packaging industries.

information on Fundamentals, Troubleshooting Maintenance of Ash Handling Plants and Pneumatic Conveying Systems for Bulk Materials. This information will help to achieve increased reliability at a decreased cost. Assemblage of this information will provide a single point of reference that might otherwise be time consuming to obtain. Most of ...

Coal Handling Systems. Ducon supplies complete coal handling systems for coal fired boilers. Coal handling at utilities requires specialized technology and equipment from unloading to crushing and dust control to fire protection.

SMG provided structural design calculations and engineering drawings for two new overland conveyors and three transfer towers. This conveyor system transfers coal from the new underground mine to an existing truck dump and into the existing conveying system, which feeds the Jim Bridger Power Plant.

Dec 05, 2015· This video shows the coal handling system which transfers coal from jetty to raw coal bunkers. The system includes transfer tower, belt conveyor, coal shed, tripper car, runoff pond, coal control ...

Nov 07, 2019· Designed for use on pulverized coal (PC) boilers, this dry ash technology removes water from the bottom ash handling equation. Commonly used in Europe, this system captures bottom ash on a steel belt/tray system. The ash is cooled as it is conveyed from the boiler and taken to a .

6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material''s external faces assume inclination at surcharge angle.

Coalfired power plants typically store coal outdoors and normally avoid using enclosed bucket elevators, making the design of a coalhandling system unique and much different than, for example, a ...

Ash / BulkHandling System Coal Handling System Speciality Conveying System EnvironmentalSystem Automation System Smart EPC Solutions Designed around your requirements. Designed for you. Mecgale was founded in 1994 as an engineering concern. During the last more than two decades, we have progressed manifold and have become a technically competent EPC [.]

Safe and efficient coal handling translates into cost savings and a boosted bottom line for coal companies. Selecting the ideal materialhandling system is essential, and Dome Technology is an industry leader not only in storage facilities but also in the optimal handling .

Conveyance Of Coal Handling Podlyanhydritove Eu. The basic function of the DC 1 unit coal handling is conveyance of coal from the handover point SD a s Doly N stup Tuimice DNT to storage tanks of individual boilers The basic conveying track of fuel to the boiler plant is solved by means of two independent lines A and B .

Jan 11, 2007· Although this article focuses on coal conveying, the principles discussed here can be applied to many other materials. The journey begins with a coal processor that incorporated a dilutephase pneumatic conveying system into production. The processor delivers a wide variety of coal .

Coal Conveying st for the 21 Мб. Editor''s Note: This article is based on a paper given at COALGEN 2011 in Columbus, Ohio. he efficient handling of coal on belt conveyors is essential to coalfired power plants.

Belt Conveyors. FEECO is the leading provider of custom conveying systems. We offer heavyduty belt conveyors for bulk handling applications. The right material handling system can add automation and fluidity to any application.

For this second edition of the Pneumatic Conveying Design Guide I have followed a similar format to the first edition, in that it is in three parts plus appendices. There the similarity ends, however, for the material within these parts has been completely updated, substantially extended and redeveloped to make it more accessible. The ...

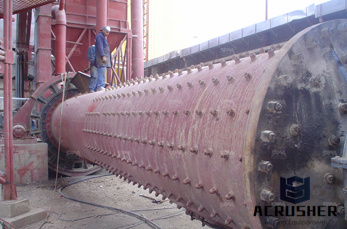

Coal Conveying Systems are a great way to transport a large amount of coal over very long distances. Our coal conveyors equipment can cut the cost of operations because of its low power consumption. For coal handling, it is best to install the equipment up to an inclination up to 20 degrees to the horizontal.

Ash handling systems may employ different forms of pneumatic ash conveying or mechanical ash conveyors. A typical ash handling system may employ vacuum pneumatic ash collection with ash conveying from several ash pick up stations and resulting in delivery to an ash storage silo for interim holding prior to load out for disposal or reuse.

WhatsApp)

WhatsApp)