Coal Mill Great Wall Corporation

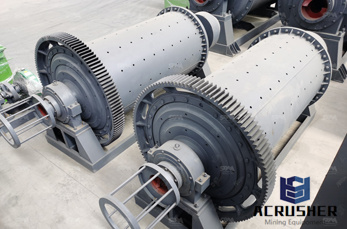

Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is also widely used to grind various hardness of coal in cement industry, metallurgy industry and .

WhatsApp)

WhatsApp)

Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is also widely used to grind various hardness of coal in cement industry, metallurgy industry and .

Vertical Coal Roller Mill Cad Ga Drawing ... Raymond mill is also called raymond roller mill,raymond grinding mill,raymond pulverizerygm series raymond mill is the new type raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive mineral materials with moh ... Heavy plant maintenance power point ...

The order also includes a large 3roller mill with a modular design featuring a drive power range of 1,000 kW for grinding hard coal and lignite with a throughput of up to 70 t/h. ... two vertical ...

Loesche is an ownermanaged engineering company founded in Berlin in 1906 and currently based in Düsseldorf, Germany that designs, manufactures and services vertical roller mills for grinding of coal, cement raw materials, granulated slag, industrial minerals and present, more than 400 people are working for Loesche in Germany and around 850 are employed worldwide.

– Conducted +150 Training Course for FD and Plant. Personnel. – Committees. • Electric Power Safety Security. Get Quote; Coal grinding systems Safety considerations PEC Consulting Group. A training program should be developed and extensive training for coal mill system operators provided on a regular basis. Safety considerations ...

Gear unit for all kinds of vertical roller mills – even coal mills. Our compact MAAG® GEAR WPU Bevel and Planetary Gearbox is your ticket to reliable power transmission in your vertical roller mill. With two series to suit your requirements, the MAAG® GEAR WPU TwoStage Gear Unit is suitable for a widerange of mills and arrangements.

Vertical Mill Coal Raymond Coal Mill 713, Vertical Roller Mill Armouring, Coal Grinding, Coal Mill Classifier, Vertical Coal Mill Operation Trend, Coal Mill System, Coal Ball Mill, Coal Mill Simens, Coal Pulverizer, Bowl Mill Coal Pulverizer, Coal Mill Reducer, Vertical Roller Mill Design, Pulverized Coal Mill, Coal Mill Cement, Roller Mill Machine, Coal Mill Grinder, Vertical Roller Mill ...

Coal Mill Training Pulveriser Vertical. Coal mill training pulveriser vertical Vertical mills Drive Technology Siemens Vertical mills such as bowl roller grinding ballandring and roller mills are slag lime gypsum and ores for the building industry and coal in the coal preparation . Online Chat Coal CrushersCoal PulverizersMillsWilliams Crusher

maintenance of pfeiffer vertical roller mill . Vertical Roller MillNHI Groupmaintenance export for vertical roller mill,Vertical roller mill is a kind of energyefficient grinding machines, which is widely used in many fields such as producing raw and clinker material, grinding slag, ore, industrial silicon, calcium carbide residue, coal gangue

Coal Vertical Roller Mill. In the coal grinding plant, the vertical grinding mill is the core equipment that directly decides the fineness and quality of final coal powder. It is not only because that the specifications of LM130M vertical coal grinding mill are suitable for the customer, but also there are some other features and advantages of ...

Coal Mill In Power Plant Main structure and wearing parts of Coal Mill. Moderator: The Coal Mill is a promising mill equipment. Compared with other mills, the Coal Mill has its own advantages. It is loved by many users. Do you understand the main structure of the Coal Mill? Every part is vital to the Coal Mill.

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particles.

Sep 11, 2013· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special ...

Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. These mills are usually found in utility plants. Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and table.

Coal vertical roller mill adopts advanced technology, finished product has highefficiency distribution and excellent combustion performance. 4. Floor space is smallest. Due to its structure features, coal vertical roller mill, compared with the same specifications, can reduce floor space and floor usecost greatly than ball mill. Working Principle

The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, feldspar, gypsum, barite and coal .

Cement grinding Vertical roller mills versus ball mills. 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials.

High Efficiency Vertical Roller Mill For Cement/slag/raw Material/coal, Find Complete Details about High Efficiency Vertical Roller Mill For Cement/slag/raw Material/coal,Vertical Roller Grinding Mill,Cement/slag/raw Material/coal Grinding Mill,High Capacity Cement Vertical Roller Mill from Mine Mill Supplier or ManufacturerXinxiang Great Wall Machinery Co., Ltd.

Coal vertical millcement production processlvssn. Coal vertical mill Capacity 558 th Applicable materials Coal quartz feldspar calcite and etc Coal vertical mill is a mechanical device used to pulverize coal for combustion in steam generator of fossil fuel power plant Enable Ginger Cannot connect to Ginger Check your internet connection or reload the browser Disable in this text field Edit ...

2 reducing the power consumption of cement clinker preparation effectively according to the display of pulverized coal measured data it can be saving electricity above 30 use of vertical roller mill production per ton cement clinker than traditional tube,Coal Grinding Power Plant Vertical Rooler Milles Training 4.

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

Vertical roller mills offer supreme grinding with high . Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range.

We are proud to be a total service provider for your coal and boiler mills and across your entire plant. To help ensure your coal milling assets are performing per your plant''s key performance indicators, we offer a full line of parts, service, and solutions: Boiler mill replacement parts; Coal mill upgrades; Mill .

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national ...

WhatsApp)

WhatsApp)