A Concrete Fix to Global Warming MIT Technology Review

Jul 23, 2008· Concrete accounts for more than 5 percent of humancaused carbondioxide emissions annually, mostly because cement, the active ingredient in concrete, is made .

WhatsApp)

WhatsApp)

Jul 23, 2008· Concrete accounts for more than 5 percent of humancaused carbondioxide emissions annually, mostly because cement, the active ingredient in concrete, is made .

Cement kiln Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year and cement kilns are the heart of this production process their capacity usually defines the capacity of the cement plant

Batch mixers are widely used machines for concrete mixing. Concrete mix obtained by this mixer is collected batch by batch and time by time. So, it is called as batch mixer. After pouring all the materials into pan or drum, it mixes all of those for some time and finally discharges. This process is ...

After the mixing process, the concrete is then transported to the machine in a wheelbarrow, where it is shoveled in to the machine, and extruded in the shape of your choice. It is then hand troweled, to a broom like protective finish, at which control joints are cut every 4 feet or so.

Making Concrete Block at Nitterhouse Masonry. The process of making a concrete masonry unit (CMU) hasn''t changed much since its inception in the early 1900''s. Raw materials are mixed with water, formed into a mold and left to cure for a period of time.

What is the Process of Making Concrete?. Before it can become a driveway, patio or foundation, concrete must be combined from a mixture of sand, aggregate or gravel, Portland cement and water. Once these ingredients are mixed together, the wet concrete product is poured into a form that serves as a mold. Within a ...

Jul 28, 2016· The earliest recorded use of concrete pipe in the United States is a sewer installation built in 1842 at Mohawk, Other New England cities followed suit and installed concrete pipelines in the second half of the nineteenth century. Many of these concrete pipelines are still in use today.

Carrying out hand mixing of concrete requires special skills and care during the process for quality control of fresh concrete. The precautions and the correct way of performing hand mixing of concrete is to undergo the mixing process as recommended by the standard procedures.

Fiber cement board are composed of cement, silica sand and wood pulp. Reinforced fiber cement products such as fiber cement board are manufactured using the ''Hatscheck Process''. The Hatsheck process was initially developed for the production of asbestos composites, but it is now used for the manufacture of nonasbestos, cellulose fiber reinforced cement composites.

Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

China Cement Block Making Machine manufacturers Select 2019 high quality Cement Block Making Machine products in best price from certified Chinese Block Making Machine manufacturers, Automatic Block Machine suppliers, wholesalers and factory on

Oct 29, 2017· Manufactured sand is a general term of artificial sand and mixed sand through the soil removing process. Mixed sand is a kind of mixture of artificial sand and mixed sand. Artificial sand, also known as machinemade sand, is the rock, mine tailing...

The concrete is supplied, depending on the plant layout by use of a transport system (02) to the concrete block making machine (03). Here, the concrete is filled into a stone mould and compacted by vibration. Products can be made with and without face mix layer.

Features of Cement Block Making Machine. Our cement brick making machines have compact structure, and the frame of the machine is made from the wearable materials, so that the machine has high strength.. Our machines have reasonable design. The distributor can feed the materials compulsorily, and the head press can generate powerful pressing force when forming the bricks.

The toe lasting machine pulls the upper down onto the last and securely bonds the two parts together in one operation. Once the shoe heel and waist of the shoe are lasted the upper is ready for the outsole. The first step of vulcanized outsole assembly process is similar to the cold cement process.

Globe''s finishing systems are tailored for the customer''s specific products and capacity requirements. Our designs are built upon decades of experience supplying the woodbased panel and engineered wood products industries, and represent a unique product line that is customized for the needs of the fiber cement .

Precast concrete is made up of coarse and fine aggregates, cement, water, and admixtures. It is mixed in the factory''s batch plant according to the concrete mix design specified by the engineer. Each Oldcastle Infrastructure plant has a concrete laboratory used to conduct routine raw material testing and control .

At the start, train cars stand ready with cement and bales of fibers. A machine processes the mixture layer by layer into panels of the desired size and thickness. However, some specific ...

Design, Construction and Testing Of a Multipurpose Brick/Block Moulding Machine * Yakubu1, Umar2 ... bricks; blocks are usually made of concrete and hollow, while bricks, on the other hand, are smaller usually made of clay or other earthen materials and solid [4]. Compressed Earth Brick (CEB) is an alternative building

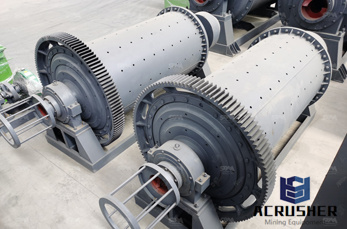

A typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to use the concrete before it hardens. An alternative to a machine is mixing concrete by hand.

The chemical process for hydraulic cement found by ancient Romans used volcanic ash with added lime (calcium oxide). The word "cement" can be traced back to the Roman term opus caementicium, used to describe masonry resembling modern concrete that was made .

Jan 02, 2016· World Amazing Modern Concrete Paving Machine ... MADE IN INDIA 799,195 views. ... Adobe in Action''s Adobe Brickmaking Process Duration: 11:08.

Learn how Hi Sibley produces 100 concrete blocks per hour as he describes the concrete block manufacturing process. Home; ... How to Make Concrete Blocks ... the mixing chamber is made .

The Concrete Construction Process. The focus of this monograph is the chemistry, microstructure, and properties of cement and concrete, not the nuts and bolts of how to mix and pour the stuff. ... Concrete can be made with a wide variety of strengths, ... The fresh concrete used is very stiff so that it can support the weight of the machine ...

WhatsApp)

WhatsApp)