formula to calculate grinding media wear rate for cement ...

Nov 09, 2017· Contact Us For Help: cement ball mill grinding media calculation cement grinding calculations in ball . DETALS ABOUT CEMENT BALL MILL GRINDING MEDIA CALCULAT...

WhatsApp)

WhatsApp)

Nov 09, 2017· Contact Us For Help: cement ball mill grinding media calculation cement grinding calculations in ball . DETALS ABOUT CEMENT BALL MILL GRINDING MEDIA CALCULAT...

Grinding Media Balls and Cylpebs Prominent Leading Manufacturer from Jaipur, we offer grinding balls, grinding media balls, hyper steel grinding media ball ( as per is 6079), grinding media, grinding media balls for africa and high chrome grinding media balls.

Nov 05, 2019· Download Cement Mill Grinding Media Wear Rate Calculation Comments. Report "Cement Mill Grinding Media Wear Rate Calculation" Please fill this form, we will try to respond as soon as possible. Your name. Email. Reason. Description. Submit Close. Share Embed "Cement Mill Grinding Media Wear Rate Calculation" ...

A discussion on the measurement of grinding media wear ... During the wet grinding of an ore inside a mill, two of those mechanisms, .... as in the case of Portland cement or kitchen salt, or when there is an attempt to .... was effective in determining the overall wear rate of grinding media, but provided no...

Sep 02, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Cement – Tube mill internals – Shell liners LINERS MADE TO LAST LONGER IN CEMENT MANUFACTURING The Group Industries manufactures Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry.

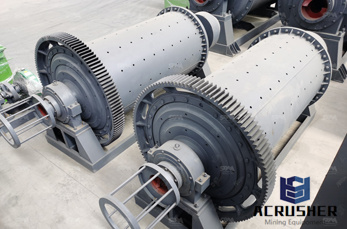

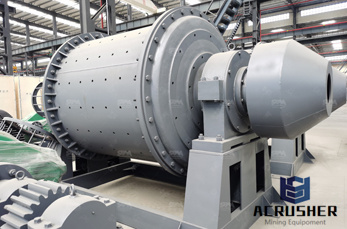

Cement grinding operation may be performed in one of the following mill setups. Ball and tube mills. Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical ...

how to estimate the wear rate for Ball mill Page 1 of 10. · Re: how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the % volumetric filling of grinding way to make track of mill main drive kW consumption reduction and add makeup .

Cement mill grinding media Wear rate calculationGrinding media wear rate Summary . learn more ; effects of grinding media shapes on ball mill . WIReDSpace. grinding. Ball size distribution inside an industrial mill was analysed in terms of shapes and sizes. Load behaviour, mill power and breakage as affected by media .. processing, cement ...

Table of ContentsData on Ball ChargesBall Mill Ball Wear ProjectionRecapitulation of Ball Wear FormulasPractical Application of Theoretical Conclusions In the previous discussion the fact was established that the work done by a ball when it strikes at the end of its parabolic path is proportional to its weight and velocity; then, since the velocity may be considered as constant for all the ...

Cement grinding Vertical roller mills versus ball mills RuCEM . applications of the vertical roller mill for cement grinding are less prevalent. ..... However, the wear rate for grinding parts of an OK mill grinding OPC is fairly low and ... It should be noted that grinding media make up around 40% of the weight of. Read More

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

terms of energy requirements and steel consumption related to grinding media and liners. Spherical grinding media are predominantly used in final stages of ore grinding. The spherical balls change shape through breakage and wear. Though this is universal in milling, its contribution and effect on milling kinetics, load behaviour and mill power

Jan 07, 2015· 2. Shape, size, and weight of the grinding media. 3. Friction between the lining and the grinding media. 4. Internal friction mill charge. Figure: Grinding media Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r The degree of ball charge varies with in the limit of 25 and 45%.

formula to calculate grinding media wear rate for cement mill. Feb 14, 2016· Ventilation of the Mill an Fan formula for grinding media charge in cement mill formula to calculate grinding media wear rate for cement mill and Cement 2014 calculate ball mill grinding media, High pressure roller press as pregrinding to ball mill,

How to estimate the Grinding media wear rate for cement grinding ball mill and how much makeup load we have add Read More Mill power calculation The Cement Grinding Office volume charging formula in ball mill grinding media charge calculation in finish cement ball mill The ball charge mill consists of formula of media .

offers 2,887 cement grinding media balls products. About 42% of these are other fabrication services, 41% are casting, and 1% are forging. A wide variety of cement grinding media balls options are available to you, such as ceramic balls, ceramic parts.

The grinding medium should provide maximum performance, minimum wear rate and highest grinding transfer to cost ratio (Jankovic, Wills, Dikmen, 2016). It is important to predict the rate of mill ...

The performance of tumbling mills is sensitive to the volumetric mill filling which influences grinding media wear rates, throughput, power draw, and product grind size from the circuit. Each of these performance parameters peaks at different filling values. In order to continuously optimize mill operation, it is vital to

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » ... and wear rate of grinding media and liners. Changing the separator to a high efficiency type brings about better residue value (on 45 micron) for the same Blaine. Alternatively, the cement can be ground to a lower Blaine with the same residue, which determines the ...

grinding media wear out rate per ton of cement. cement mill grinding media wear rate , How to estimate the Grinding media wear rate for cement grinding ball mill and how much makeup, wear rate value on cement mill grinding media per ton cement, [Chat Online] High wear rate at mill inlet than the mill outlet shell,

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the % volumetric filling of grinding way to make track of mill main drive kW consumption reduction and add makeup .

Cement mill grinding media Wear rate calculationGrinding media wear rate Summary . Get Price. Cement – Tube mill internals – Grinding media AIA Engineering Ltd. Wear Resistant grinding media and grinding balls for cement plants from AIA Engineering.

Wear of grinding media. One of the major problems regarding the use of ball mills is to balance the size distribution of grinding media into the mill, which is determined by the speed of consumption and rate of replacement, as the wear of the grinding balls requires

WhatsApp)

WhatsApp)