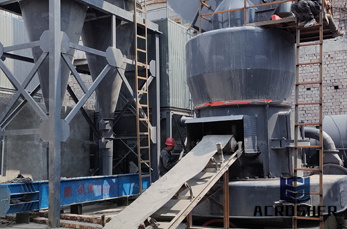

coalmill classifier

Coal Mill Classifier Repair Case Study | Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace. Hot air, from the air .

WhatsApp)

WhatsApp)

Coal Mill Classifier Repair Case Study | Duromar The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace. Hot air, from the air .

RSG Inc, located in Sylacauga, Alabama specializes in fine powder technology. The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industries.

There have been very few conversions of UK coal mills from static to dynamic classifiers. But test experience with a dynamic classifier at Powergen''s RatcliffeonSoar power station has demonstrated significant fineness gain, especially at the coarse end of the particle size distribution curve, and minimal effect on mill coal throughput and operability, with greatly reduced in vibration levels.

Obtain a full range of applicable fuel analyses as well as necessary drawings, dimensions and data on the boiler, burners, classifiers, coal conduits, mills, feeders and fans. Perform mill internal inspections, looking for wear, erosion, corrosion, inappropriate modifications, missing or broken parts, or nonfunctioning parts.

For most static classifier designs in use, there is the ability to increase coal fineness. This generally involves one or more of the following three adjustments: Insertion or lengthening of the ...

Nov 17, 2012· COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY . ... in Pulverizer Erosion by mineral particles picked up in the air stream carrying pulverized coal through the mill, classifier, exhauster, and transport pipe is a recognized problem. Erosion can produce holes in steel liners and deep depressions in large section cast ...

Coal Char Classifier Mill perfectday. coal char classifier mill, coal mills, 2 With torrefied materials or chars there is likely to be a finer product and The modification of the classifier vanes . Free Quote; Get Price; Types Of Classifiers In Coal Mills bioresins. function of dynamic classifier on coal mill in india.

everywhere the coal is handled, processed or stored, including railcars, HE HE COAL MILL COAL MILL Derek Stuart, AMETEK Land, and Todd Collins PE, Hoosier Energy, US, discuss available techniques for detecting early signs of mill fires and explosions. Hoosier Energy Merom power plant.

coal mill classifier upgrade mineral grinding machinery. What Are Classifiers In Coal Mills grinding mill equipment. An improved vane of the type adapted for use in the classifier cage of a bowl mill type coal pulverizer The improved vane is designed such that Get Price ...

Most existing pulverizers—both the verticalshaft and ballmill types—come with a static classifier. Its blades reject coarse particles to produce a stream of coal particles that are mostly ...

The SAS Adjustable High Spin Static Classifier Retrofit is a proven and reasonable alternative to making the substantial capital commitment required for Dynamic Classifiers. SAS customers have achieved 6% to 15% capacity improvements, while concurrently reaching % thru 50 mesh and % thru 200 mesh fineness levels – grinding at 42 HGI coal.

Welcome to Classifier Milling Systems. Classifier mills are particularly complex structures. At Classifier Milling Systems, our selection of flexible powder processing equipment and expertise regarding classifier mills is incomparable. Our team''s commitment to the customer sets a higher standard in the industry.

Mar 31, 1987· The drawing shows a partial section of a rollerandbowl mill for a pulverizedcoal furnace, in the mill housing 1 of which the grinding part 2 is accommodated with the truncatedconeshaped classifier 3, arranged above the latter, and the coaxial coal feeder tube 4.

Integrated in the mill. Since 1996 Loesche has been using dynamic classifiers of the LSKS series (LOESCHE bar cage classifier) in virtually all mills. The LSKS classifier has proven itself as an excellent separation machine with a high selectivity for mill product.

The SAS Adjustable High Spin Static Classifier Retrofit is a proven and reasonable alternative to making the substantial capital commitment required for Dynamic Classifiers. SAS customers have achieved 6% to 15% capacity improvements, while concurrently reaching % thru 50 mesh and % thru 200 mesh fineness levels – grinding at 42 HGI coal.

Coal Chutes: Upgrades done at Arnot, Hendrina and Kriel Power Stations. Arnot Power Station: Classifier, as well as louvre ring upgrades on the Loeshe Mills. Classifier and Coal Feed systems for the Stein Mills on Unit 1. (Part of the Capacity Increase Project )

Coal Mill Feeders. In order to cater to requirements of clients, we are offering Coal Mill Feeders to them. Learn More. Spiral Classifiers. On account of our rich industry experience and our expertise, we are offering Screw Classifiers to our clients. ... we, KH SYSTEMS, ...

Pulverizer Wikipedia, the free encyclopedia For example, a pulverizer mill is used to pulverize coal for combustion in the ... These mills are also designated as an example size, BBD4772, .... grinding table that is supported and driven by a planetary gear reducer directcoupled to a motor. ...The dynamic classifier, which consists of a stationary angled inlet vane ...

classifier, which consists of a cone equipped with adjustable vanes, is an option at a lower cost since it contains no moving parts. With adequate mill grinding capacity, the MPS mill equipped with SLK static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or

Function Of Coal Pulverizer . function of coal pulverizer biciavventura. function of classifier in coal pulverizer. what is the function of Pulverizer machine Pulverizer, Wikipedia, the free encyclopedia The ball and tube mills are low, speed machines that grind the coal with steel The primary air input in the case of in pulverizer .

sized material is not reentrained into the air and coal stream entering the classifier. PERFORMANCE Classifier technology in the Power Industry has improved significantly with the advent of rotating classifiers. Compared to mill operation with a statictype classifier, the SLS clas sifier offers a number of performance advantages.

Coal Mill Classifier Repair PROBLEM. The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace. Hot air, from the air side of the air preheater, is pulled through the coal mill by the exhaust fan (refer CH801) picking up the fine coal dust and feeding it to the furnace.

these three factors, all bowl mills are cataloged in terms of "base capacity", which is defined in terms of a coal of 55 Hardgrove and a fineness of 70% passing 200 mesh. All sizes are available with static or dynamic classifiers to accommodate a wide range of product fineness. The mill is readily adaptable to a wide variety of appli

Williams High Efficiency Turbine Air Separators can help increase production rate from various grinding mills including vertical roller mills, ball mills, and others. These high efficiency air classifiers can achieve 80% efficiency while producing 70% minus 200 mesh (74 microns) and 70% efficiency when producing 95% minus 200 mesh (74 microns).

WhatsApp)

WhatsApp)