Creative Engineering Consultants Corporation | Better ...

This organization is not BBB accredited. Grinding Machine in Little Rock, AR. See BBB rating, reviews, complaints, more.

WhatsApp)

WhatsApp)

This organization is not BBB accredited. Grinding Machine in Little Rock, AR. See BBB rating, reviews, complaints, more.

Derived from our previous research, a new micro drill bit with higher accuracy and productivity was developed. Because the drill flute plays a significant role in its cutting performance, the design of grinding wheel profile for the new micro drill flute by an inverse problem method is .

MicroTech CNC Machine Tools Private Limited, is a new venture of MICROTECH Group of Companies. It was incorporated in Bangalore, India. The main activity of the new company is "Sales Service" of High Precision CNC Machines, Large Size Moving Column Machining Centers, High speed micro EDM Drilling Machines, Surface Profile Grinding Machines and Ultra Precision Hard Finish Turning ...

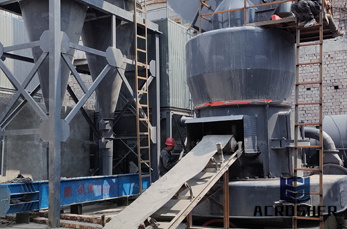

MicroGrinding Systems, Inc. offers a range of services at our Little Rock, Arkansas facility, including the following: Custom Grinding. We can custom grind virtually any material to your specifications.

Machine tools are developed with the possibility of producing the micro geometry (cutting edge design) of micro tools as well as plating processes to produce super abrasive micro grinding tools. Applying these setups, we are able to produce ultrasmall micro grinding and micro milling tools with typical diameters of 50 µm and down to 4 µm.

Learn how to improve the quality and speed of your metallographic grinding and polishing – from selecting the best method to choosing the right consumables – with expertise, tips and insight from Struers, the world''s leading materialographic and metallographic experts.

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones) Handheld power tools such as angle grinders and die grinders;

Microplus Engineering Ltd are a highly experienced CNC sliding head machining and centreless grinding company covering the West Midlands and UK wide.

We cover cutting and grinding from cover to cover. CTE is the industry''s most comprehensive source for finding manufacturers, distributors and machine shops serving the metalworking industry.

In the recent times, microgrinding process emerged as a solution for the micromachining of hard and brittle materials where diamond and cubic boron nitride (CBN) abrasive tools were used [6,7]. Microgrinding can be done at very small depth of cuts so that ductile mode material removal can .

Get directions, reviews and information for Micro Grinding Systems in Little Rock, AR. Micro Grinding Systems 1823 E 17th St Little Rock AR 72202. Reviews (501) Website. Menu Reservations Make Reservations . Order Online Tickets Tickets See Availability Directions ...

Mechanical Engineering Design Projects; The above list of mechanical engineering mini projects is provided by nevonprojects for study and research on mechanical system. Our researchers constantly research on latest mechanical engineering projects topics and ideas to find the best mechanical mini projects topics for study and research.

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth.

High Precision Machining. ... We have developed revolutionary fixturing techniques and creative programs to achieve surface finishes less than 8 micro inch (.2 micro meter) while holding critical tolerances to ± .0002 inch (± .005 millimeter). ... Precision Grinding. With over 60 years of precision grinding knowledge and experience, we have ...

Shop online at for wireless speakers, Bluetooth headphones, Sound Blaster sound cards, gaming headsets. Free shipping on orders over 35.

Sep 24, 2018· In the micro grinding process, geometrically deviated structures are common due to the low depth of cuts compared to the size of abrasive grits. Moreover, abrasive grits random distribution on the tool surface is also a factor. In most of the cases, the number of grits participating in the grinding process is countable, unlike macro grinding ...

About Us. Creative Engineering is a high precision honing machine and SPM Machine manufacturer based at Bangalore, India. We have vast years of experience in Honing Technology and we are supplying for plateau type honing machines like a Servo and Hydraulic Vertical Honing Machine, Horizontal Honing Machine, Auto stroking Honing Machine, CNC Honing machine, Honing Equipments etc and also ...

Sep 23, 2013· Schläfli Engineering Ltd., Bnhofstrasse 22, 3294 Büren, SWITZERLAND Tel: + Email: info Schläfli designs ...

creative engineering micro grinding. A significant machining methodMicro End Grinding (MEG), is used for micro parts made of hard and brittle materials in this paper. As an important parameter of the grinding process, the grinding temperature is closed to the machined surface quality and the grinding wheel wear, etc. Creative Precision: Phoenix ...

Apr 19, 2013· Making screw threads on parts that are only inch in diameter requires unique skills, but such micro threads are required for a large variety of products, such as watches, eyeglasses, cell phones, cameras, circuit boards, medical devices and miniature aerospace safety and control devices.

National Jet 7M with M2000 programmable controller, stereo microscope..001" to .010" dia.

We can perform surface and cylindrical grinding operations on external and internal faces on a variety of material including ceramics. T. +44 (0)1639 842526 E. info Wecori Ltd

Creative Engineering Co. DBA. Micro Grinding Systems. 103 connections. View Mike Winn''s full profile. It''s free! Your colleagues, classmates, and 500 million other professionals are on LinkedIn.

Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials. The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling. Grinding employs an abrasive product, usually a rotating wheel brought into

WhatsApp)

WhatsApp)